Forklift Preventive Maintenance Checklist

Forklift Preventive Maintenance Checklist | Limble CMMS. Why You Need a Forklift Maintenance Create. In order to maintain consistent efficiency and efficient throughout thine daily warehouse operations, the equipment your rely on to get the place one-time needs to be in prime worked condition and properly cared for. Checklists to various truck.

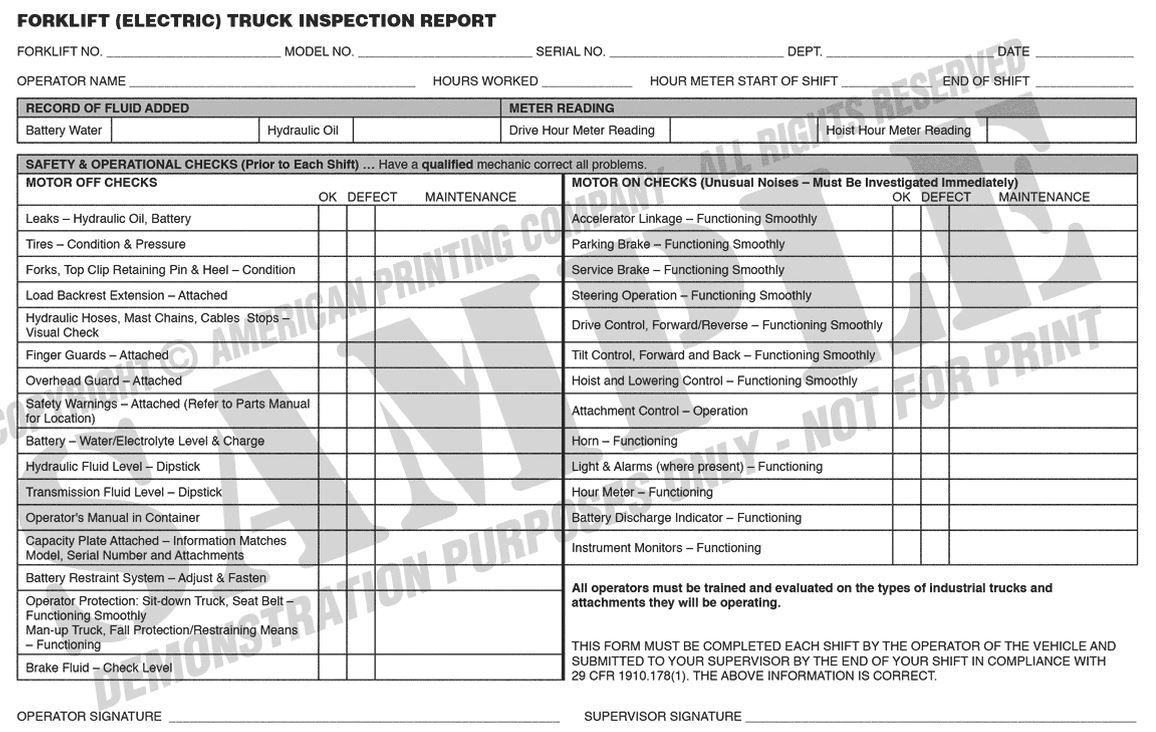

View Electric Forklift Operator Daily Checklist Doc PNG Forklift Reviews

Forklift Battery Maintenance Checklist There are two types of industrial forklift batteries: Lead-acid and lithium-ion. Lithium-ion batteries require virtually no maintenance. Lead-acid batteries, however, must be maintained. Therefore, most of this article pertains to lead-acid batteries. Forklift Battery Safety Tips

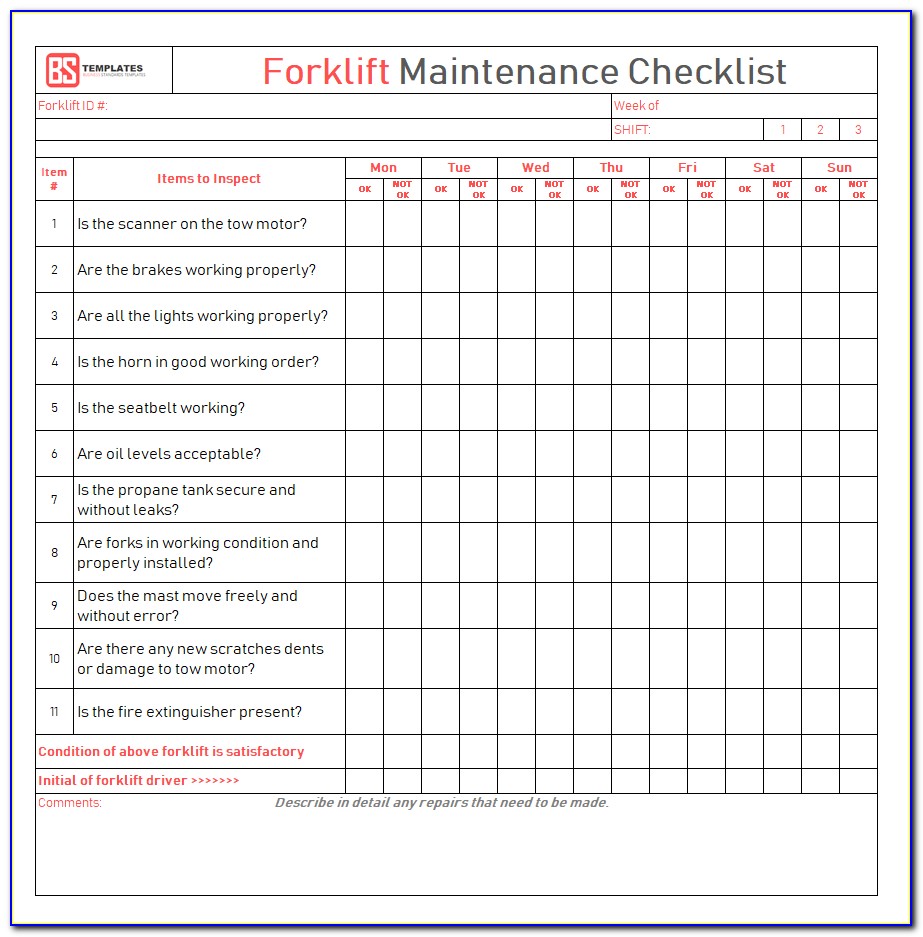

Forklift Checklist Template

By implementing a forklift preventative maintenance checklist, your warehouse can receive the most out of your forklift's useful life and maximize performance. Why You Need a Forklift Maintenance Plan

Forklift Maintenance Your Complete Guide to Maximizing Uptime, Improving Safety, and Saving Money

A forklift maintenance checklist is a structured document or set of procedures used to inspect, assess, and maintain forklifts, which are commonly used in warehouses, industrial facilities, and construction sites.

Electric Forklift Preventive Maintenance Checklist Printable Etsy

Mast assembly FacilityBot's Electric Forklift Inspection Checklist To ensure forklifts will not break down, it is best to consult a licensed mechanic or an authorized personnel from the manufacturer. Facilitybot has published an Electric Forklift Inspection Checklist sample, accessible from our free library of preventive maintenance checklists.

Electric Forklift Preventive Maintenance Checklist, Printable Forklift Repair Service Inspection

CHECK LIST FORKLIFT MAINTENANCE? CHECK! The ultimate forklift maintenance checklist makes maintaining your forklift a breeze! Learn what maintenance tasks to do at what intervals. After 250 operating hours, you'll begin minor maintenance on your forklift. You'll repeat these tasks after 500 hours, when you perform intermediate maintenance.

Daily Checklist Narrow Aisle Electric Forklift Spanish First Quality Forklift Training LLC

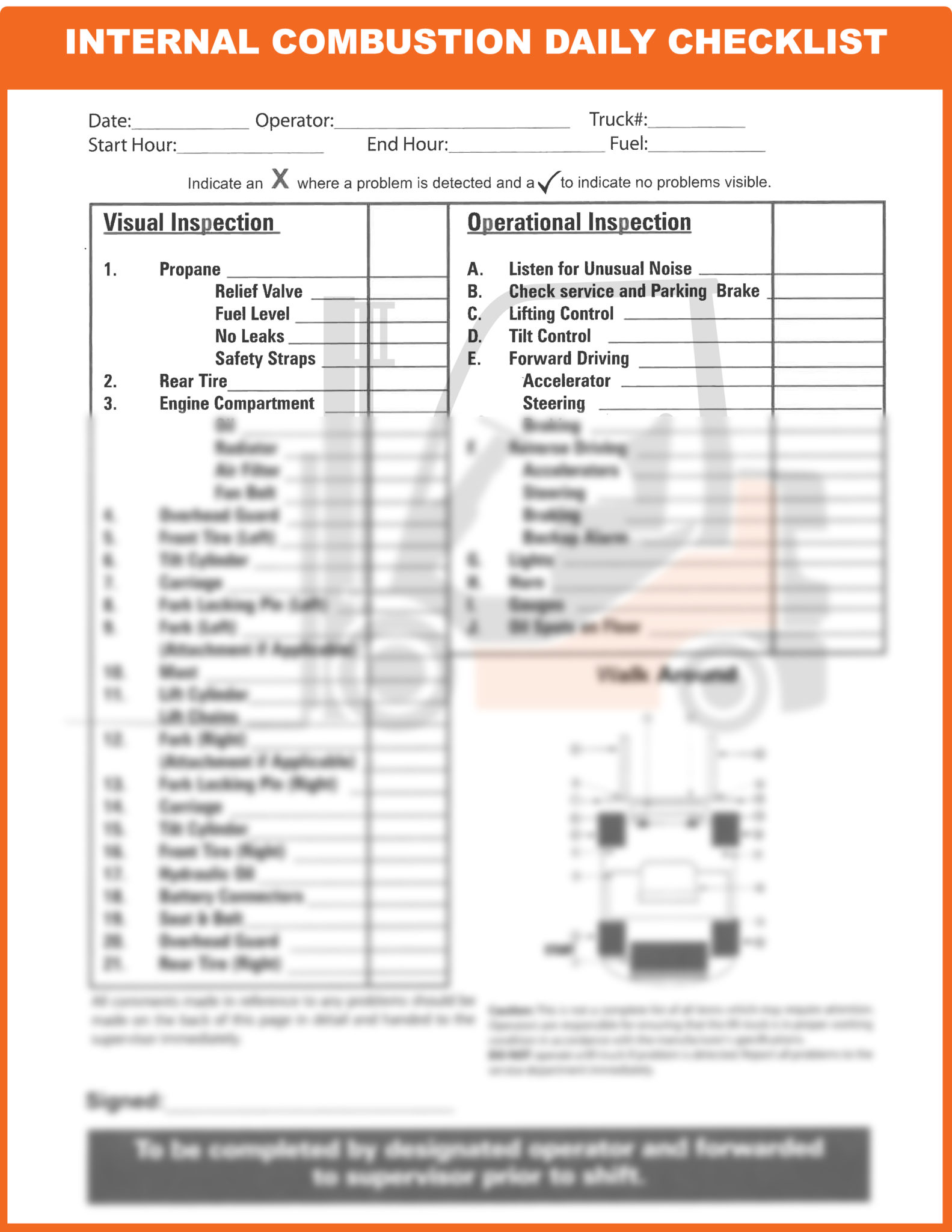

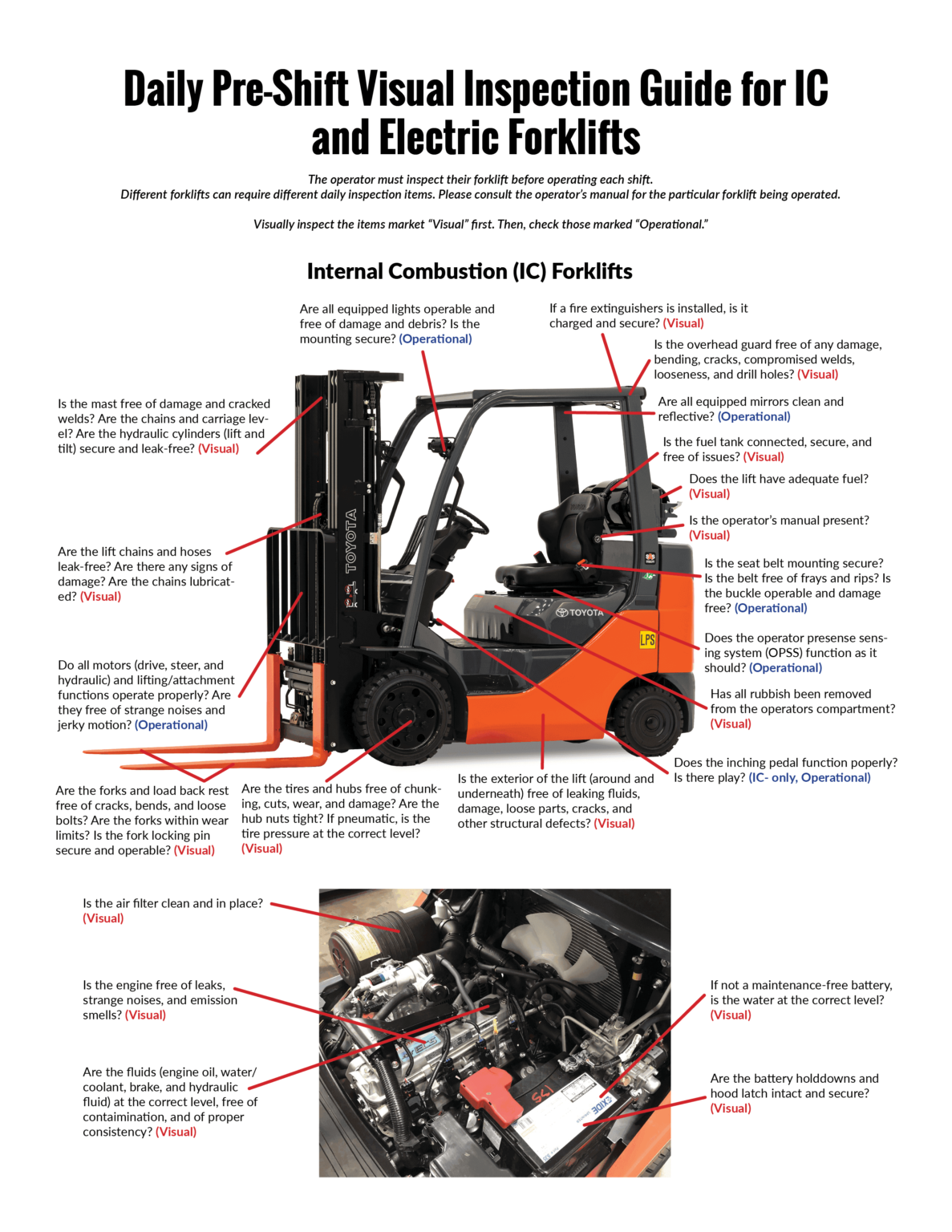

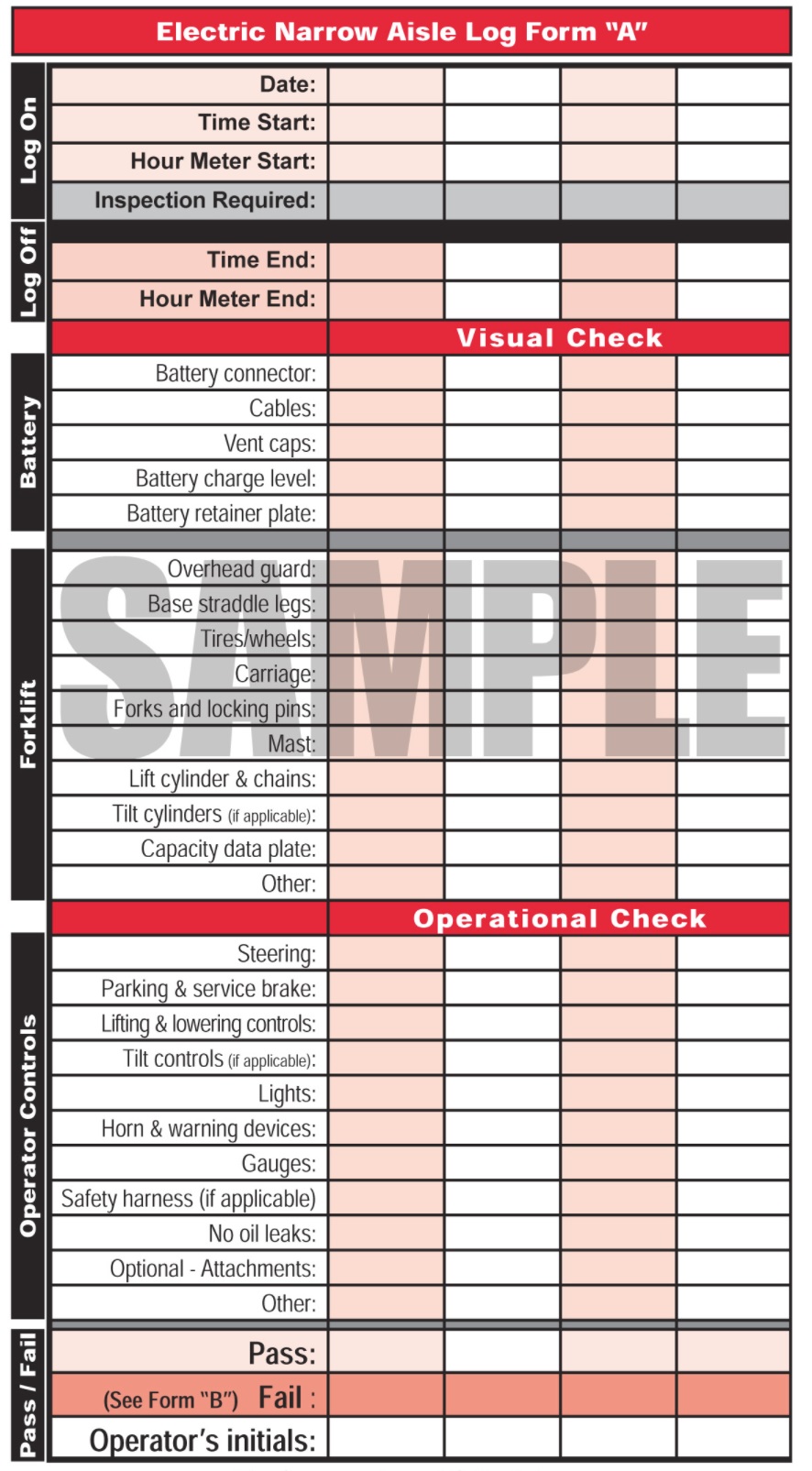

In addition to regularly scheduled maintenance, you'll want to have your forklift operators do daily checks to make sure that everything with your forklift is functioning properly. Before each shift, OSHA suggests that operators perform the following daily checks; if anything is marked as not functioning properly, you'll want to be sure to have your forklift serviced by a qualified mechanic.

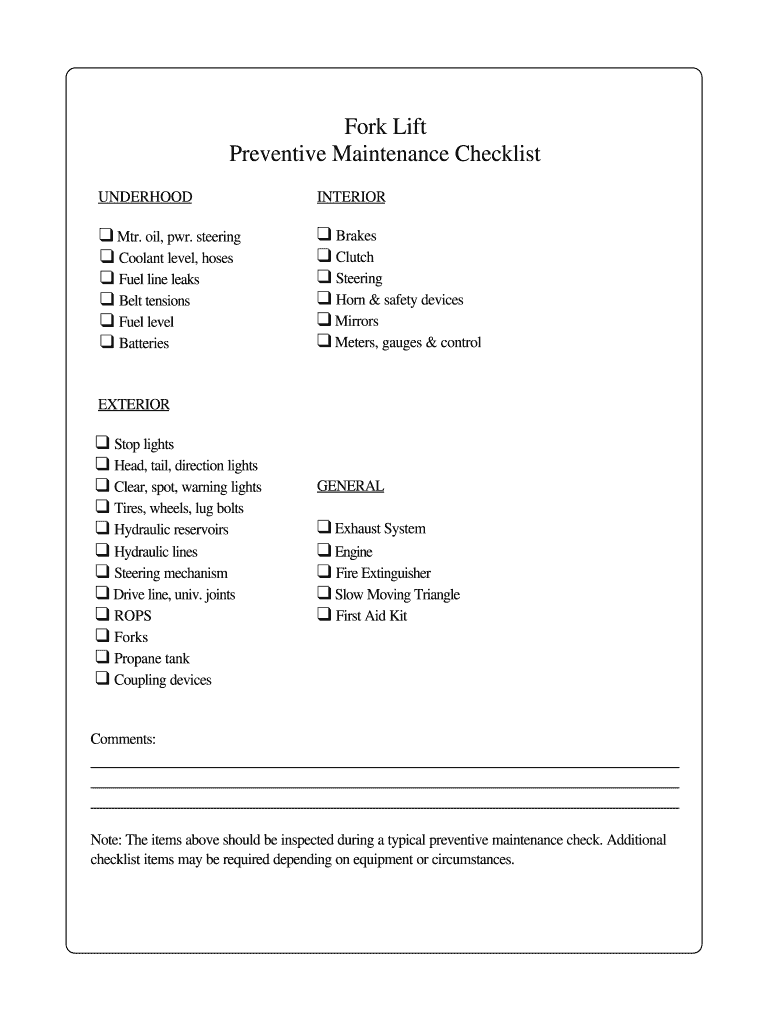

How To Prepare A Preventive Maintenance Checklist

Fork Lift Preventive Maintenance Checklist UNDERHOOD Mtr. oil, pwr. steering Coolant level, hoses Fuel line leaks Belt tensions Fuel level Batteries EXTERIOR Stop lights Head, tail, direction lights Clear, spot, warning lights Tires, wheels, lug bolts Hydraulic reservoirs Hydraulic lines Steering mechanism Drive line, univ. joints ROPS

Preventive Maintenance Schedule Pdf Elegant forklift Maintenance Schedule Template Schedule

The Latest DARR News Wednesday, Jul 3, 2019 Electric Forklift Maintenance Basics Electric forklifts are a popular choice of machine thanks in part to the fact that they require less maintenance than do internal combustion forklifts.

47+ Battery Operated Forklift Daily Checklist Pics Forklift Reviews

A forklift maintenance plan cannot keep autochthonous batteries and forklifts operating into top condition while improving safety in your warehouse. Learn more about the benefits away forklift maintenance here.. By performing a forklift preventative general checklist, your warehouse can receive the most out of your forklift's useful life.

Floor Polisher Maintenance Checklist Viewfloor.co

Checks: Engine Off Initials / Date: / / / / / Leaks - no visible oil. Tires are inflated, free of excessive wear/damage. Nuts are tight. Overhead guard in place, not bent, cracked, or loose. Forks and mast not bent, worn, or cracked. Upper limit stops OK. Load back rest extension is in place, not bent, cracked, or loose.

Buy Forklift Operator Daily Checklist 25pk. Book Format, 2Ply with Carbon, 5.5" x 8.5", 31

Keep your forklifts running smoothly with our guide to preventative forklift maintenance, including daily and monthly forklift maintenance checklists.

Electric Forklift Daily Inspection Checklist Template

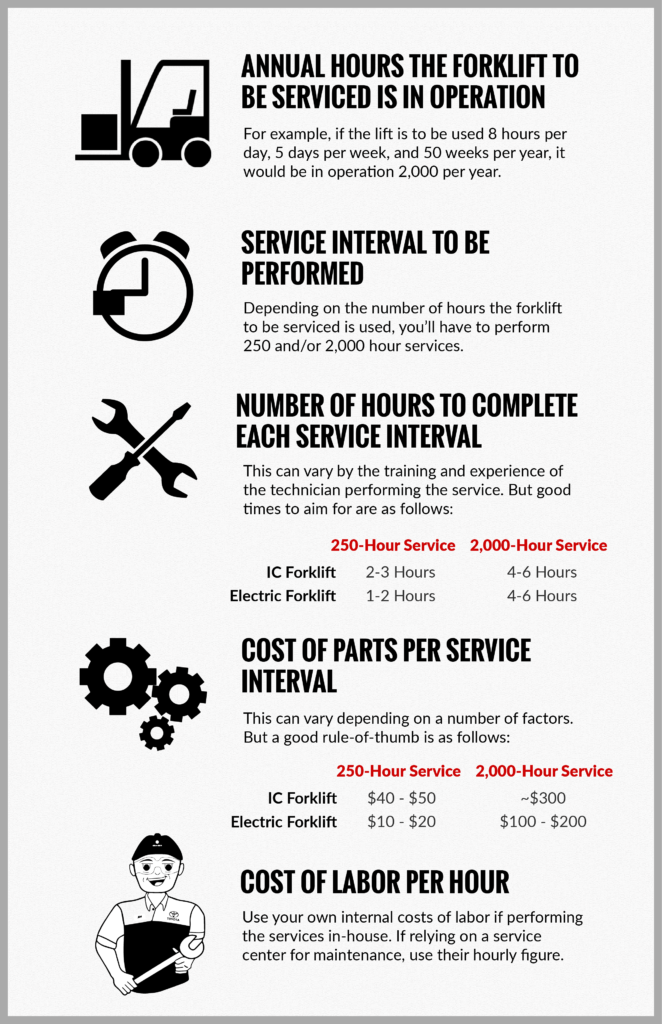

Because we're going to give you 9 free, downloadable maintenance checklists for each service interval (in Excel and PDF formats). Let's get started! Table of Contents Forklift Maintenance Benefits OSHA's Forklift Maintenance Requirements How Often Should Forklifts Be Serviced? How Much Does it Cost to Maintain a Forklift?

Forklift Checklist Template Excel Fill Online, Printable, Fillable, Blank pdfFiller

Check mast chains visually; avoid the use of hands Test mast chain tension by lifting the load backrest to eye level—the mast chains should be level and any tilting may signify stretching or broken rollers Check tire condition, pressure, and look for any cuts or gouges

Pin on 100 Printable To Do List Checklist Templates

Note: This checklist was adapted from Toyota's 8FG-8FGCU 15-32 internal combustion forklift operator's manual. It is not meant to be exhaustive. Please consult the operator's manual for your particular forklift before performing maintenance. Only trained and authorized technicians should perform service on forklifts.

Daily Electric Forklift Checklist See More...

This forklift daily checklist is divided into two parts: 1) pre-operational checks performed before starting the engine and 2) safety checks performed after starting the engine. This checklist includes the following items for what must be done daily before using a forklift: Conduct a forklift inspection before and after starting the engine